NDT - It Will Test You

Non-Destructive Testing Program is Alive

There is no doubt that your life has been saved not once, not twice, but hundreds of times because of non-destructive testing. When you get on a plane, the engines that propel it are tested using NDT methods. The parts that make up your car’s brake system, the welds on the bridges you drive over, and even the parts in your cell phone, were tested using NDT.

NDT is a wide variety of testing methods used to evaluate engineering materials and their properties without causing damage to them. These tests ensure a product's integrity and reliability. They help to avoid failures, prevent accidents and to save human lives.

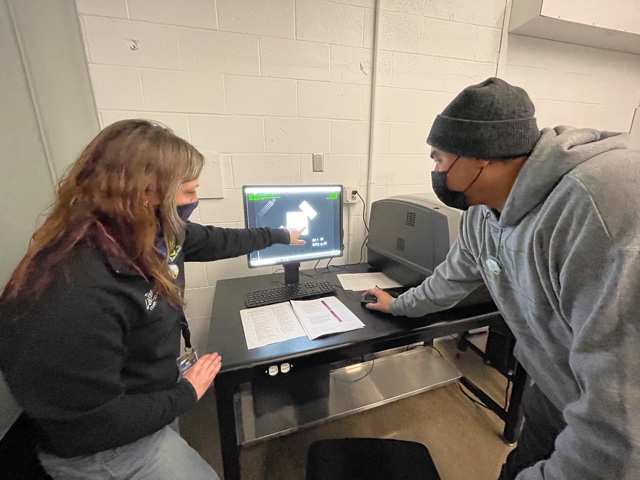

|

| Xray equipment in the NDT lab |

Formerly known as the Metallurgy program, NDT has been a staple at LBCC for decades. The department has two full-time instructors, Scott Ballard and Zachary Milligan, and one Instructional Assist faculty member, Emily Whittier.

Milligan, who is currently in his third year teaching at LBCC, is certified under the American Society for Nondestructive Testing as a level III ultrasonic testing and liquid penetrant inspector. Before coming to LB, he was a level III inspector at the American Technical Institute, where he administered their NDT training program.

“I got into non-destructive testing because I love the idea that the parts we’re inspecting are critical to peoples lives and infrastructure,” Milligan said. “This career is challenging and the different testing methods keep it interesting.”

Students who go through the NDT program at LB will learn five of the main testing methods used: ultrasonic, radiography, liquid penetrant, magnetic particle testing, and visual testing.

Ballard, who has taught here for six years, earned his degree in metallurgy from LBCC and went on to get his masters in teaching, where he later spent 22 years teaching high school manufacturing classes.

“I’ve spent my career educating people to work in the trades and I’m passionate about it because it offers tremendous employment opportunities for students,” Ballard said. “There is so much opportunity locally, regionally and even internationally for students. Two of our recent graduates are both working outside the US right now.”

|

| NDT lab ultrasonic testing equipment |

NDT is a two-year program and students who complete it will earn an Associate of Applied Sciences degree. The local job outlook is good with companies like ATI and Selmet locally. Outside of the local area, students can expect to work in areas such as aerospace, defense or even the medical field inspecting things like MRI machines.

According to instructor Milligan, the employment rate among students graduating the program is “pretty close to 100% and that students can expect their starting wage to fall between as little as $19 to as much as $32 per hour.”

Bella Luchia, a second-year student, got into NDT because she wanted a career in the trades that was less demanding on her body.

“I wanted to work in the trades because I like working with my hands, and I didn’t see a point to a four-year degree,” Luchia said. “When I’m 20, I’ll be on track to buy my own house and maybe have a new car. And I won’t have lots of student debt.”

If you’re interested in getting more information about the NDT program, you can contact Scott Ballard at ballars@linnbenton.edu, or Zachary Milligan at milligz@linnbenton.edu.

Comments

Post a Comment